The Industrial Internet of Things (IIoT) has revolutionized industries by connecting machines, devices, and systems to the internet, allowing for real-time data monitoring and analysis. However, as technology continues to advance, the path forward for IIoT now includes the integration of artificial intelligence (AI) and automation. In this article, we’ll explore how AI and automation are shaping the future of Industrial IoT and the potential benefits they offer to various industries.

The Evolving Role of IIoT

The traditional role of IIoT has been to collect and transmit data from industrial devices. This data has been invaluable for monitoring equipment health, optimizing processes, and reducing downtime. However, the next phase of IIoT involves going beyond data collection and into data analysis, prediction, and automation.

AI and IIoT: A Perfect Match

Artificial intelligence plays a pivotal role in elevating IIoT to new heights. By leveraging machine learning algorithms, AI can process the massive amounts of data generated by IIoT devices and extract valuable insights. Here are a few key ways AI and IIoT are working in harmony:

- Predictive Maintenance: AI can analyze equipment data to predict when machinery is likely to fail. This proactive approach to maintenance helps prevent costly downtime and improves asset longevity.

- Anomaly Detection: AI can identify abnormal patterns in data, signaling potential issues or security breaches. This ensures early intervention to mitigate risks.

- Optimized Operations: AI can continuously monitor processes and make real-time adjustments to optimize efficiency and reduce energy consumption.

- Quality Control: AI-powered cameras and sensors can inspect products for defects, ensuring consistent quality in manufacturing.

Automation and IIoT: Streamlining Operations

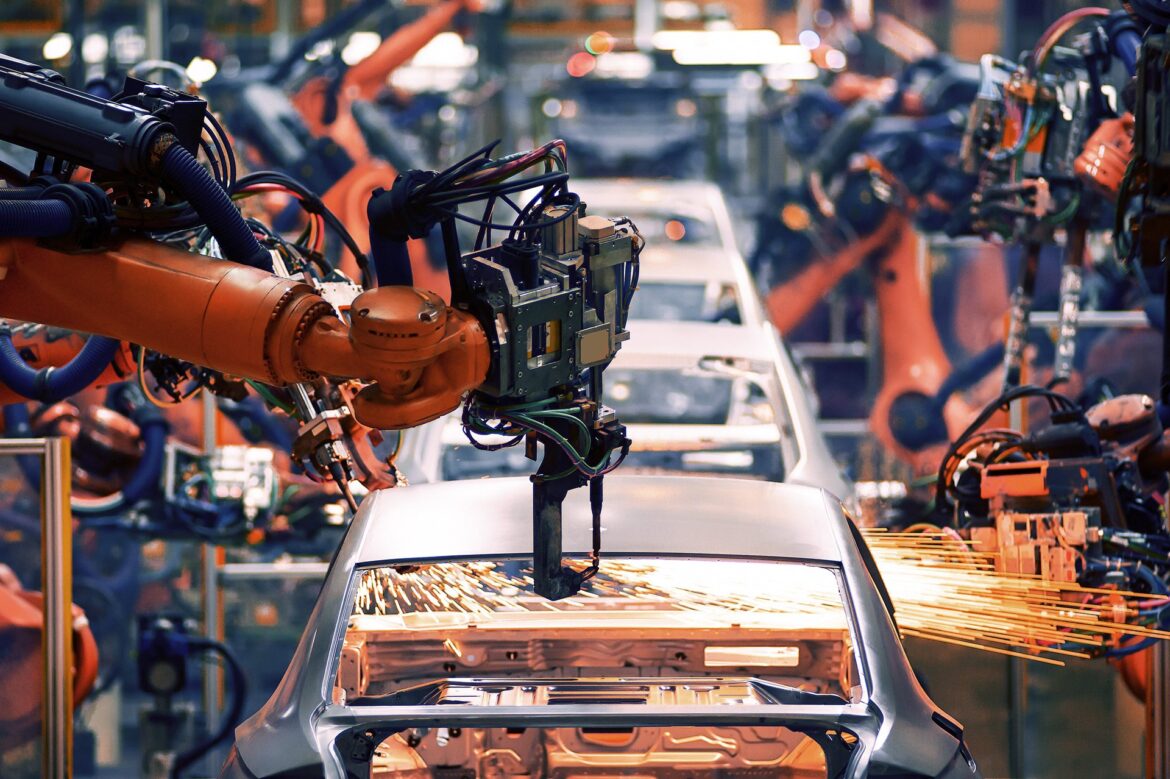

Automation, when integrated with IIoT, allows for the execution of tasks without human intervention. This combination results in several advantages:

- Reduced Labor Costs: Automation can handle repetitive and labor-intensive tasks, reducing the need for manual labor and the associated costs.

- 24/7 Operation: Machines equipped with IIoT sensors and automation capabilities can operate around the clock, increasing production efficiency.

- Improved Safety: Dangerous tasks can be delegated to automated systems, reducing risks to human workers.

- Enhanced Productivity: Automated processes can be fine-tuned for maximum efficiency, leading to higher productivity.

Applications Across Industries

AI and automation in IIoT are not limited to a single industry. They offer benefits across various sectors:

- Manufacturing: Automation and AI-driven quality control improve product consistency and manufacturing efficiency.

- Energy: Predictive maintenance and process optimization reduce energy consumption in power plants.

- Agriculture: AI-driven automation helps with precision farming, optimizing crop yields and resource usage.

- Healthcare: AI and IIoT devices support remote patient monitoring and personalized healthcare.

Challenges and Considerations

While the integration of AI and automation in IIoT is promising, it comes with challenges, including data security, privacy concerns, and the need for upskilling the workforce to manage and maintain these advanced systems.

Conclusion

The path forward for Industrial IoT involves the seamless integration of artificial intelligence and automation. This convergence is transforming industries, enhancing productivity, and improving efficiency and safety across the board. As businesses continue to adopt these technologies, we can expect a future where AI and automation are at the heart of industrial operations, shaping a more connected and intelligent world. The synergy of IIoT, AI, and automation offers a path towards a more prosperous and sustainable future.