The world of manufacturing is undergoing a profound transformation, driven by the integration of advanced technologies that are collectively known as Industry 4.0. These technologies encompass the Industrial Internet of Things (IIoT), artificial intelligence (AI), big data, and automation, and they are reshaping the way goods are produced. The Industrial Internet Consortium (IIC) is at the forefront of this revolution, leading the charge in exploring and implementing intelligent manufacturing practices. In this article, we delve into the realm of intelligent manufacturing and the pivotal role played by the Industrial Internet Consortium.

The Rise of Intelligent Manufacturing

Intelligent manufacturing, often referred to as “smart manufacturing,” is the next phase in the evolution of industrial production. It leverages cutting-edge technologies to create highly adaptive, efficient, and responsive production systems. This approach empowers manufacturers to optimize their operations, enhance product quality, and quickly adapt to changing market demands.

Key Components of Intelligent Manufacturing:

- Industrial Internet of Things (IIoT): The foundation of intelligent manufacturing, IIoT connects machines, devices, and systems to the internet, enabling real-time data collection and analysis. This connectivity enhances visibility, efficiency, and control across the entire manufacturing process.

- Artificial Intelligence (AI): AI brings cognitive capabilities to manufacturing operations. Machine learning algorithms are employed to analyze vast datasets, make predictions, and optimize processes. AI-driven decision-making enhances quality control, predictive maintenance, and resource allocation.

- Big Data and Analytics: Manufacturing generates a vast amount of data. Big data analytics tools help transform this data into actionable insights. These insights can be used to improve product quality, reduce downtime, and enhance overall efficiency.

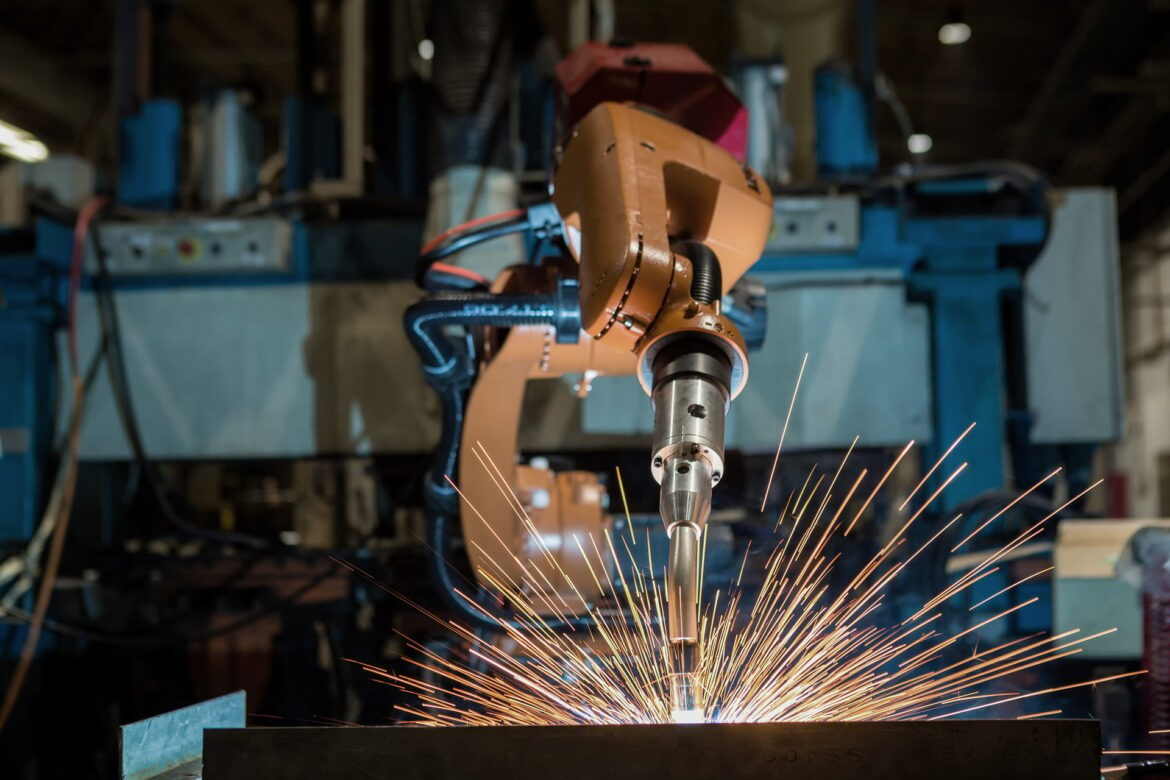

- Automation and Robotics: Automated systems and robots are integrated into the manufacturing process to handle repetitive tasks, reduce human error, and increase productivity.

The Role of the Industrial Internet Consortium

The Industrial Internet Consortium is a global organization dedicated to accelerating the growth of the Industrial Internet. It brings together industry leaders, researchers, and technology experts to collaborate on developing best practices, frameworks, and testbeds for the integration of advanced technologies in manufacturing.

- Setting Standards: The IIC plays a crucial role in developing industry standards and frameworks that enable the seamless integration of IIoT, AI, and automation. These standards ensure interoperability, security, and scalability in intelligent manufacturing systems.

- Collaborative Research: The IIC fosters collaborative research initiatives, often in the form of testbeds. These real-world testing environments allow companies to experiment with cutting-edge technologies and validate their effectiveness in manufacturing processes.

- Education and Knowledge Sharing: The IIC actively promotes knowledge sharing, providing resources, best practices, and educational materials to help manufacturers understand and implement intelligent manufacturing.

- Driving Innovation: By bringing together industry leaders and innovators, the IIC serves as a driving force for innovation in intelligent manufacturing. It encourages the development of new solutions and technologies that can revolutionize the industry.

The Benefits of Intelligent Manufacturing

The adoption of intelligent manufacturing practices offers a wide range of benefits:

- Enhanced Efficiency: Automation and real-time data analysis streamline production processes, reducing waste and increasing efficiency.

- Improved Quality: AI-driven quality control and predictive maintenance ensure that products meet high standards consistently.

- Flexibility and Adaptability: Intelligent manufacturing systems can quickly adapt to changes in demand or product specifications.

- Reduced Downtime: Predictive maintenance and efficient resource allocation minimize production disruptions.

- Cost Savings: By optimizing resource usage and reducing waste, manufacturers can achieve significant cost savings.

Conclusion

Intelligent manufacturing, driven by the integration of IIoT, AI, and automation, is revolutionizing the industrial landscape. The Industrial Internet Consortium is playing a pivotal role in advancing these technologies and ensuring their effective integration. As manufacturers explore the possibilities of intelligent manufacturing, they are poised to become more efficient, adaptable, and competitive in a rapidly changing market. The IIC’s commitment to setting standards and fostering collaboration positions it as a driving force behind the future of manufacturing, one where intelligence and automation are central to success.