Digital Twin Technology: A Journey Through Time and Its Future in Industrial Automation

Digital Twin Technology has rapidly evolved into a cornerstone of modern industrial automation, offering unparalleled insights into systems and processes. Let’s dive into the history, key advancements, and the promising future of this transformative innovation.

A Brief History: The Origins of Digital Twin Technology

The concept of digital twins dates back to the early 2000s. It was first introduced by Dr. Michael Grieves at the University of Michigan in 2002 during a product lifecycle management (PLM) course. Grieves envisioned a digital representation of physical systems to improve their design, monitoring, and optimization.

However, the foundation for digital twins was laid even earlier. NASA pioneered similar ideas in the Apollo program during the 1960s. They used physical simulations of spacecraft systems on Earth to troubleshoot issues in real time, which aligns with the digital twin concept in its infancy.

In the 2010s, the advent of Industry 4.0 and advancements in IoT, AI, and data analytics brought digital twins to industrial automation, enabling real-time data integration and predictive capabilities.

Key Applications in Industrial Automation

- Predictive Maintenance

- By analyzing real-time data, digital twins predict potential failures, reducing downtime and maintenance costs.

- Example: Monitoring turbines in power plants to avoid unexpected breakdowns.

- Process Optimization

- Simulations allow industries to test and refine production processes without halting operations.

- Example: Optimizing manufacturing lines to improve throughput.

- Energy Efficiency and Sustainability

- Digital twins track energy use and emissions, helping industries meet sustainability goals.

- Design and Testing

- Virtual prototypes replace physical ones, saving time and resources in product development.

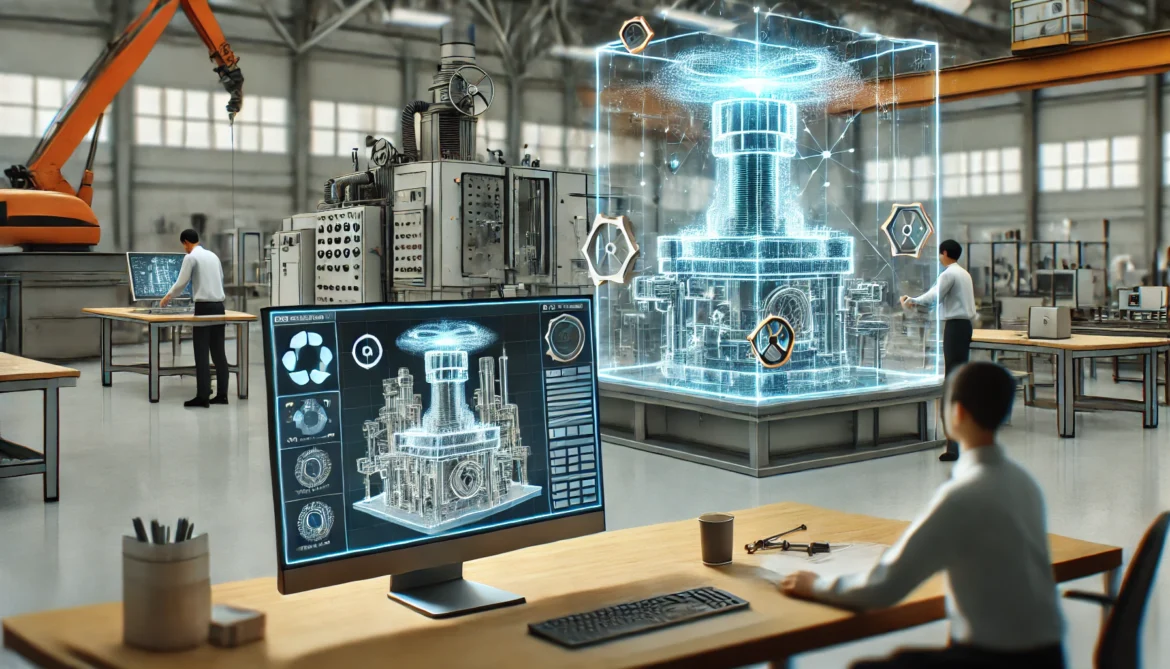

How Does Digital Twin Technology Work?

- Physical Asset Integration: Sensors and IoT devices collect data from machines, providing a real-time view of their status.

- Virtual Modeling: This data feeds into a virtual replica, simulating the asset’s performance and behavior.

- Data Analytics: AI and machine learning analyze the twin, offering insights for optimization and decision-making.

- Feedback Loop: Insights are applied back to the physical system, creating a continuous cycle of improvement.

Future Prospects for Digital Twin Technology

The future of digital twins is promising, with trends indicating rapid expansion in capabilities:

- Integration with AI and AR/VR:

- Enhanced visualization through AR/VR will improve training and troubleshooting. AI will further optimize predictions and processes.

- Sustainability Enhancements:

- Digital twins will be critical in achieving net-zero emissions goals, enabling industries to design greener systems.

- Global Adoption Across Industries:

- From healthcare to smart cities, digital twins are poised to revolutionize diverse sectors.

- Scalable Solutions for SMEs:

- As technology becomes more affordable, small and medium enterprises (SMEs) will adopt digital twins for automation and optimization.

Leading Companies in Digital Twin Technology

The digital twin technology market features several leading companies excelling in different industries and use cases. Here are some top players to consider :

- Siemens: Their Xcelerator platform integrates advanced digital twin solutions, offering applications across the manufacturing, energy, and automotive sectors. It includes tools for real-time simulations and predictive maintenance.

- IBM: With its Maximo Asset Monitor, IBM provides AI-driven insights, real-time monitoring, and anomaly detection for enterprise asset management. It’s widely used in infrastructure and industrial asset optimization.

- Microsoft: The Azure Digital Twins platform enables the creation of virtual models of real-world environments. It supports complex IoT integrations, real-time data analysis, and system optimization.

- GE Digital: Specializing in industrial applications, their Predix Digital Twin offers predictive maintenance and performance optimization, particularly for aviation and energy systems.

- Bentley Systems: Their iTwin platform is tailored for architecture, engineering, and construction (AEC) industries, enabling infrastructure modelling and lifecycle management with real-time updates.

- Dassault Systèmes: Known for 3DEXPERIENCE, this platform focuses on comprehensive digital twin solutions for product design and manufacturing, widely used in aerospace and healthcare.

- PTC: Its ThingWorx platform delivers IoT-enabled digital twin solutions for connected devices, emphasizing customization and integration.

Challenges Ahead

Despite its potential, digital twin technology faces hurdles:

- High Implementation Costs: Advanced sensors, software, and integration are expensive.

- Cybersecurity Risks: Real-time data sharing makes systems vulnerable to cyberattacks.

- Skill Gaps: The need for expertise in AI, IoT, and automation slows adoption.

Conclusion

From its conceptual roots in NASA’s Apollo missions to its modern applications in industrial automation, digital twin technology has come a long way. It is not just a tool for efficiency but a gateway to innovation and sustainability. As industries embrace this technology, the line between the physical and digital worlds continues to blur, paving the way for smarter, more connected systems.