Components of a PLC System

In industrial automation, Programmable Logic Controllers (PLCs) serve as the central nervous system, orchestrating and controlling a wide array of manufacturing processes, machinery, and systems. A PLC system comprises various components that work together seamlessly to monitor inputs, execute logic functions, and generate outputs, thereby automating and optimizing industrial operations. In this comprehensive guide, we will explore the essential components of a PLC system, their functions, and their role in driving efficiency, reliability, and productivity in industrial environments.

1. Central Processing Unit (CPU):

At the heart of every PLC system lies the Central Processing Unit (CPU), which serves as the brain responsible for executing control logic, processing inputs, and generating outputs. The CPU interprets the program stored in memory and executes instructions sequentially to control the operation of connected devices and machinery. It typically consists of a microprocessor, memory modules (RAM and ROM), and various interfaces for communication and input/output (I/O) connections. The CPU’s processing power, speed, memory capacity, and communication capabilities play a crucial role in determining the overall performance and functionality of the PLC system.

2. Input/Output (I/O) Modules:

Input/Output (I/O) modules act as the interface between the PLC and external devices such as sensors, switches, actuators, and other field devices. They enable the PLC to receive input signals from sensors and switches, process them according to the programmed logic, and generate output signals to control actuators and devices in the industrial environment. I/O modules come in various types, including digital inputs/outputs (DI/DO) for handling discrete signals (on/off), analog inputs/outputs (AI/AO) for processing continuous signals (voltage, current, temperature), and specialty modules for specific applications (e.g., high-speed counting, motion control). The selection of appropriate I/O modules depends on the specific requirements of the application, such as the number of I/O points, signal types, and environmental conditions.

3. Power Supply Unit:

The Power Supply Unit (PSU) is responsible for providing electrical power to the PLC system, ensuring stable and reliable operation of all components. It converts incoming AC or DC voltage from the power source into the required voltage levels needed to power the CPU, I/O modules, and other internal circuitry of the PLC. The PSU typically includes features such as overvoltage protection, short-circuit protection, and thermal protection to safeguard the PLC system against electrical faults and fluctuations in power supply. Selecting an appropriate power supply unit with adequate capacity and redundancy is essential to ensure uninterrupted operation and prevent downtime due to power-related issues.

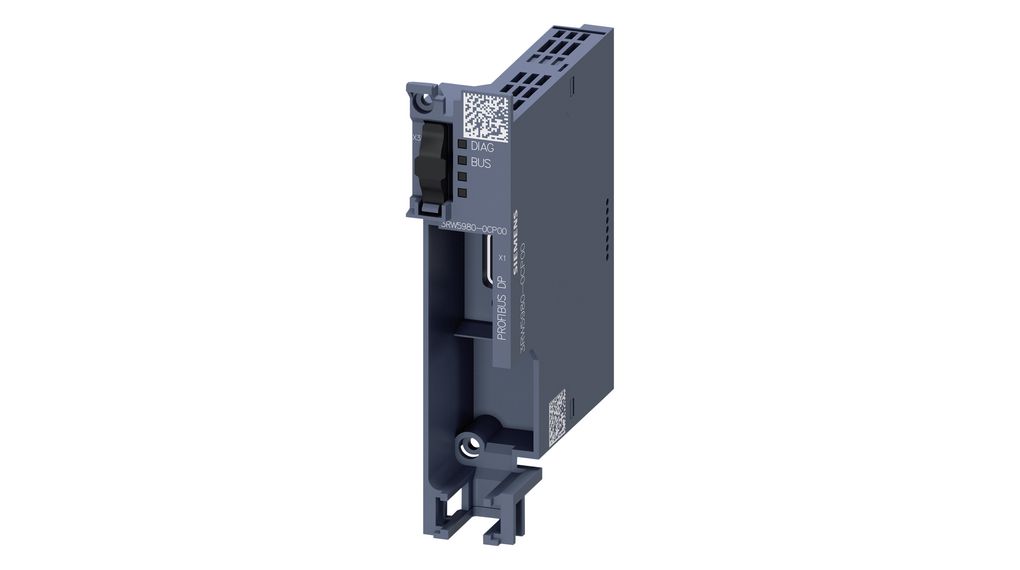

4. Communication Modules:

Communication modules enable the PLC to communicate with external devices, networks, or control systems, facilitating data exchange, remote monitoring, and control capabilities. They support various communication protocols and interfaces, such as Ethernet, serial communication (RS-232, RS-485), and fieldbus protocols (Profibus, Modbus, DeviceNet). Communication modules allow the PLC to integrate seamlessly with other automation components, such as Human-Machine Interfaces (HMIs), Supervisory Control and Data Acquisition (SCADA) systems, Programmable Automation Controllers (PACs), and distributed control systems (DCS). They play a vital role in enabling real-time monitoring, remote diagnostics, and centralized control of industrial processes, enhancing efficiency, and productivity.

5. Programming Device:

The Programming Device serves as the interface for developing, editing, and uploading/downloading PLC programs to the CPU’s memory. It typically consists of software running on a computer or handheld device connected to the PLC via a programming cable or communication network. The Programming Device allows engineers, technicians, or programmers to create and debug PLC programs using various programming languages, such as ladder logic, function block diagrams, structured text, or sequential function charts. It provides tools for configuring hardware settings, defining I/O mappings, configuring communication parameters, and monitoring real-time data during program execution. The Programming Device plays a crucial role in the development and maintenance of PLC applications, enabling users to implement complex control logic, troubleshoot issues, and optimize system performance.

6. Expansion Racks and Modules:

Expansion Racks and Modules provide scalability and flexibility to the PLC system, allowing for expansion and addition of additional I/O points, processing power, and functionality as needed. Expansion racks provide additional slots for inserting I/O modules, communication modules, or specialty modules, expanding the PLC’s capacity to handle larger and more complex control applications. Expansion modules offer specialized functions or features, such as high-speed counting, motion control, analog signal processing, or temperature monitoring. They allow users to customize the PLC system to meet specific requirements and adapt to changing needs over time. Expansion racks and modules play a crucial role in future-proofing the PLC system and ensuring its compatibility with evolving technologies and applications.

7. Human-Machine Interface (HMI):

The Human-Machine Interface (HMI) serves as the user interface for interacting with the PLC system, providing operators, engineers, and technicians with visual feedback, status information, and control capabilities. The HMI typically consists of a touchscreen display, control buttons, indicators, and graphical elements that allow users to monitor process variables, view alarms, acknowledge faults, and control equipment remotely. HMIs enable intuitive and user-friendly interaction with the PLC system, simplifying operation, maintenance, and troubleshooting tasks. They play a vital role in enhancing productivity, efficiency, and safety in industrial environments by providing operators with real-time access to critical information and control functions.

Conclusion:

In conclusion, a PLC system comprises various components that work together seamlessly to automate and control industrial processes effectively. From the central processing unit (CPU) and input/output (I/O) modules to power supply units, communication modules, programming devices, expansion racks/modules